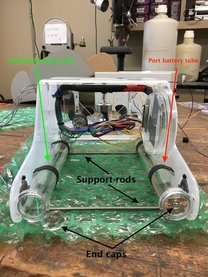

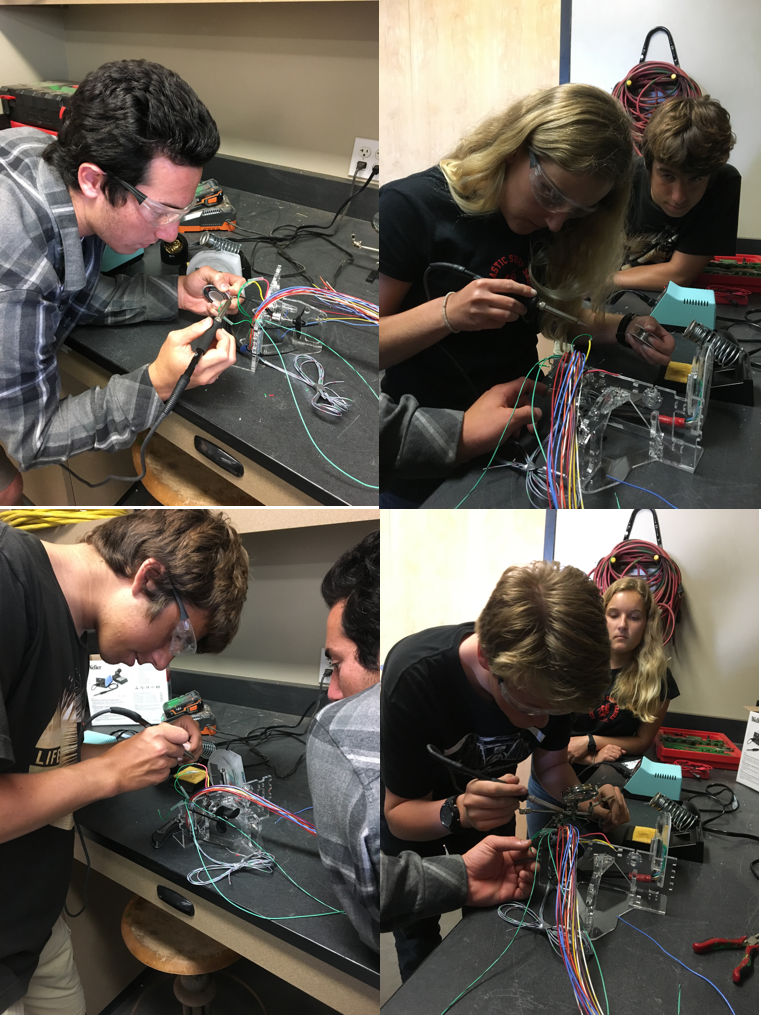

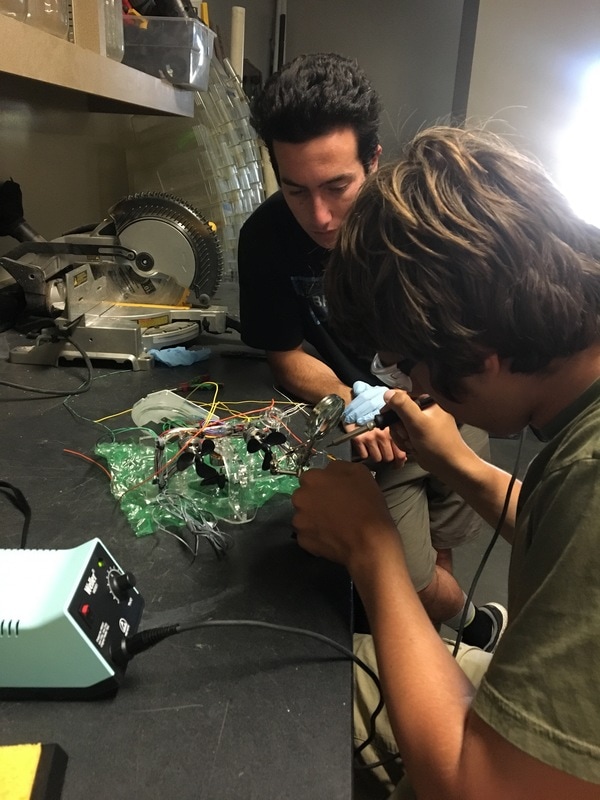

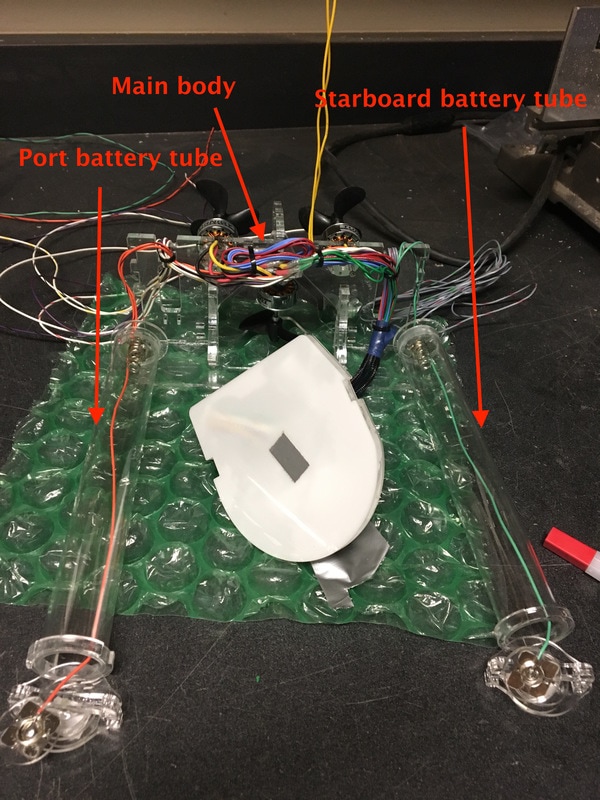

Project Pegasus team members go over the day's instructions Project Pegasus team members go over the day's instructions This week’s module was big milestone; today we finally started assembling the main body of Pegasus. After spending so much time solvent-welding acrylic and soldering connections, the team and I were really excited to secure the main body, battery tubes, and camera chassis to the outer frame of the ROV. The Edwards Lab was able to purchase an Inertial Measurement Unit (IMU)/depth sensor combo. This tiny sensor, about the size of a standard Lego™ brick, contains a gyroscope, accelerometer and a depth sensor so we can get real-time measurements of Pegasus’s pitch, roll and depth underwater. All of this meant that we had another tricky set of connections to solder. But, as always, the team members of Project Pegasus rose to the occasion. Here’s what Aaron has to say: “Up until today, the ROV was just a bunch of parts and pieces laying. I could feel the energy in the team once every component was set in place to make the ROV look like an actual ROV! The team completed steps 27 and step 5 on the IMU depth sensor and module. We each had a turn at connecting the IMU which was one heck of an extensive job! In the end we were able to make the IMU and connections look outstandingly amazing. The next step was getting the battery tubes mounted up by solvent-welding the battery end caps. Everything was smooth sailing until we applied epoxy to the battery end caps [to water-proof them] when we discovered epoxy leaking into the battery tube itself! Luckily we caught this before it was too late [when we submerge Pegasus in the water]” Aaron makes a good point; as we get toward the end of the build-phase of Project Pegasus we really can’t afford to make any mistakes. While Pegasus is really coming together, we’ve got a lot of work ahead of us before our little ROV can actually jump in the water.

Stay tuned, these next few steps should be pretty interesting! Cheers, -Baron von Urchin

0 Comments

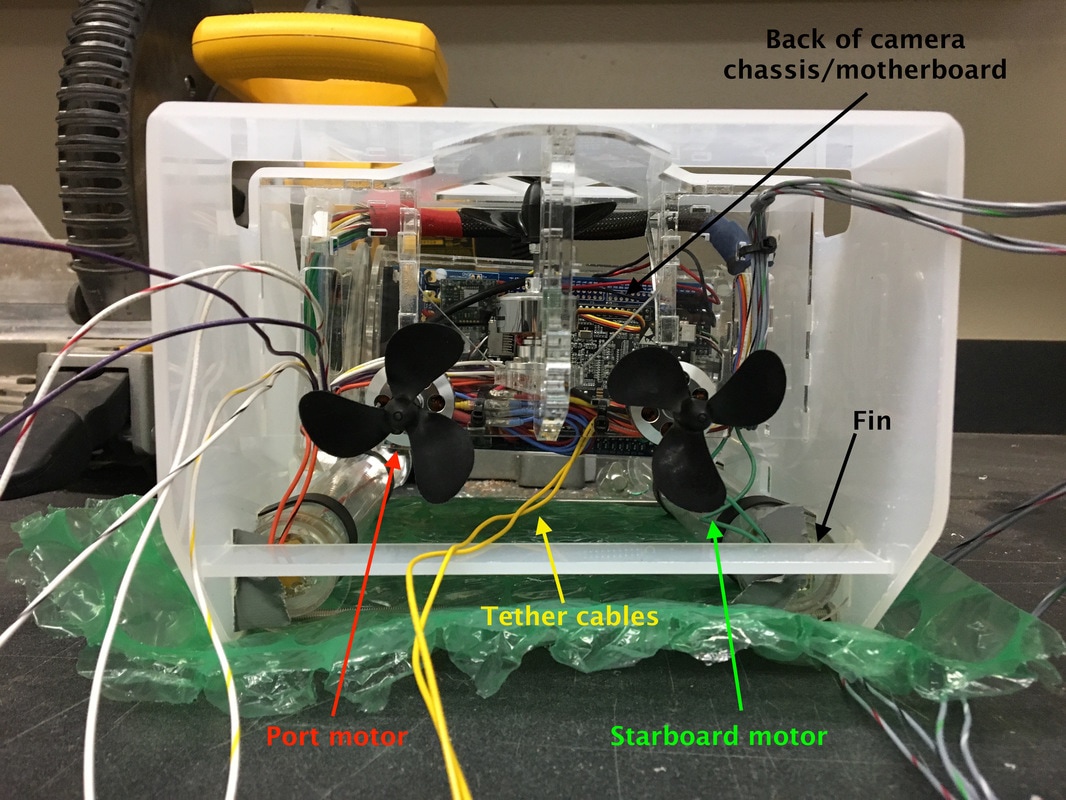

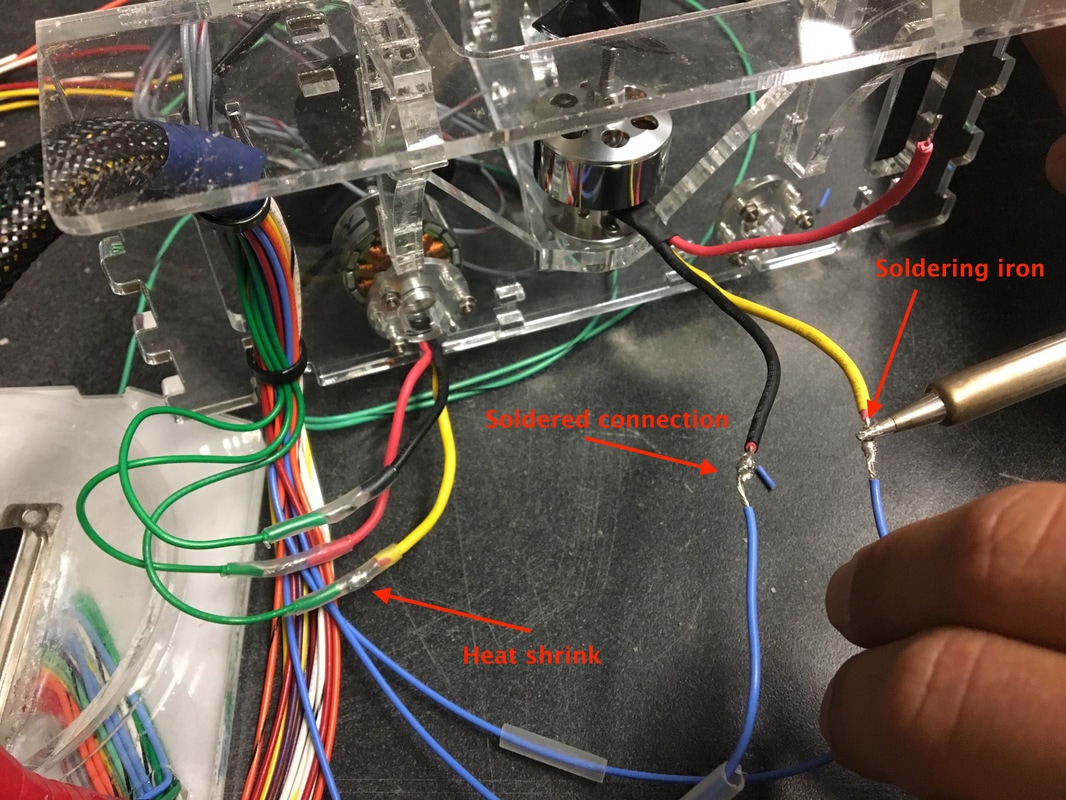

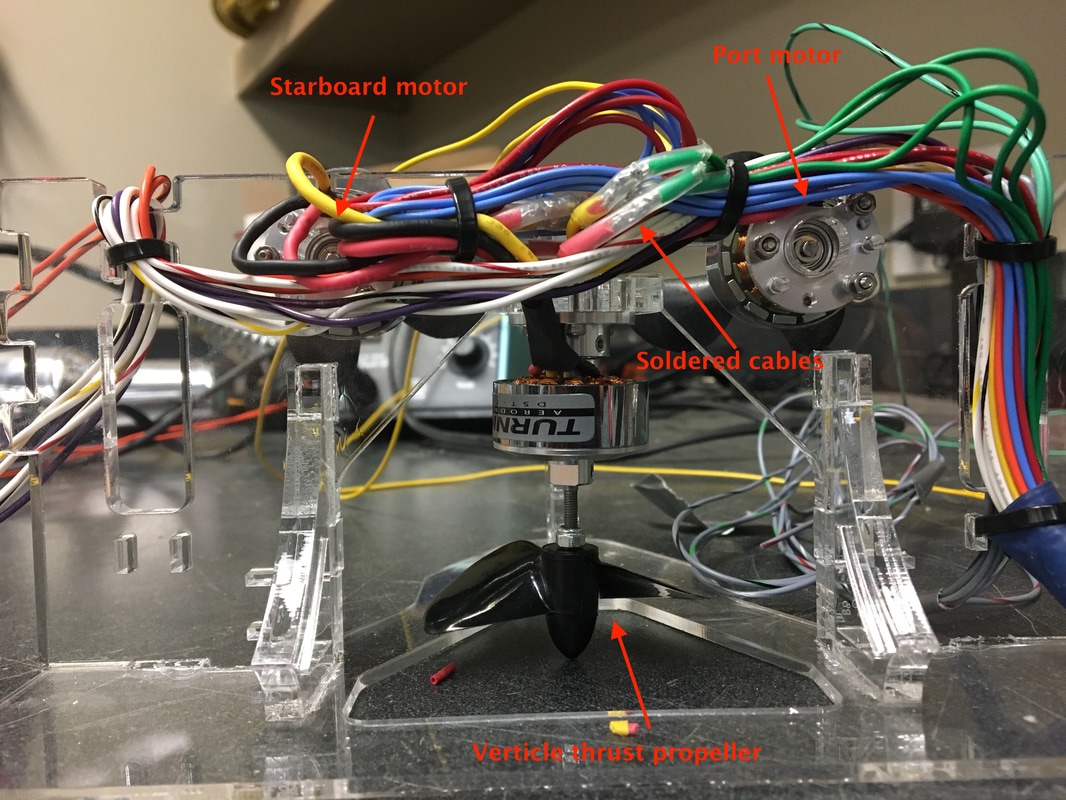

Every module starts with unpacking pieces and prepping material. Some days are easier than others Every module starts with unpacking pieces and prepping material. Some days are easier than others 4/26/2017 San Diego, CA Project Our module today saw us back at the soldering station, prepping wires and mounting the ROV’s motors. Unfortunately, we got off to a rough start and our team learned a valuable lesson early on today: always come prepared with the right tools. Due to a lack of wire strippers (forgotten by yours truly), we quickly had to improvise; we had to find a way of stripping the rubber insulation off of the wires without cutting the wire itself. This proved to be no easy feat, but I am proud to say that the team held it together with grace and patience and at the end of the day everything worked out. Here’s what team member Lorenzo had to say: “Today is the day we finally get to put together the wire routing and motors for Pegasus (our ROV). It was a very exciting build because we were able to attach the motors with propellers to the main body. There are three motors on the ROV; port and starboard (left and right) motors drive the propellers which give the ROV directional thrust. The third motor provides vertical thrust. Once we finished prepping the motor we soon began working on the wiring of Pegasus itself by soldering some of the main wires that were color coded to match the motor wires. To do this we striped the appropriate wires from the DB-25 connector and the motor wires. There are three wires for the motor which means we had to solder three connections per motor! The soldering today was a major challenge as we had to figure out how to strip the wires without wire cutters and to wrap the exposed wires together. To protect the soldered connections (from water and stress) we melted plastic tubing (called "heat shrink") on to the connections as any exposed wire is dangerous and must be covered by something that doesn’t conduct electricity. Wire routing was also a challenge as we had to figure out what wires go in what direction and should be attached at which point to the inner frame of Pegasus. We used zip ties to clearly organize the wires, which will make the inner components of the ROV run more smoothly. Even though we made a few mistakes along the way, we learned from them and it all worked out in the end. This module brought the team closer together; solving tough challenges when things go wrong and learning from them is all part of the process when working on a project like this one. I am very happy, each day brings new exciting challenges and builds as we are almost finished building our ROV. In the end, the experiences and a chance to help others with what we are doing is the important part of all as this and soon we’ll be able to fly Pegasus in the ocean.” Well said Lorenzo! We’re just a few more build-days away from completing the construction of Pegasus! At this point soldering, acrylic welding and cooperation are second nature to Project Pegasus interns, and I couldn’t be more proud.

Be sure to check back in as we work towards getting Pegasus built and in the water! Cheers, Baron von Urchin |

AuthorPike Spector is currently a Research Operations Specialist with Channel Islands National Marine Sanctuary Archives

August 2022

Categories |

RSS Feed

RSS Feed