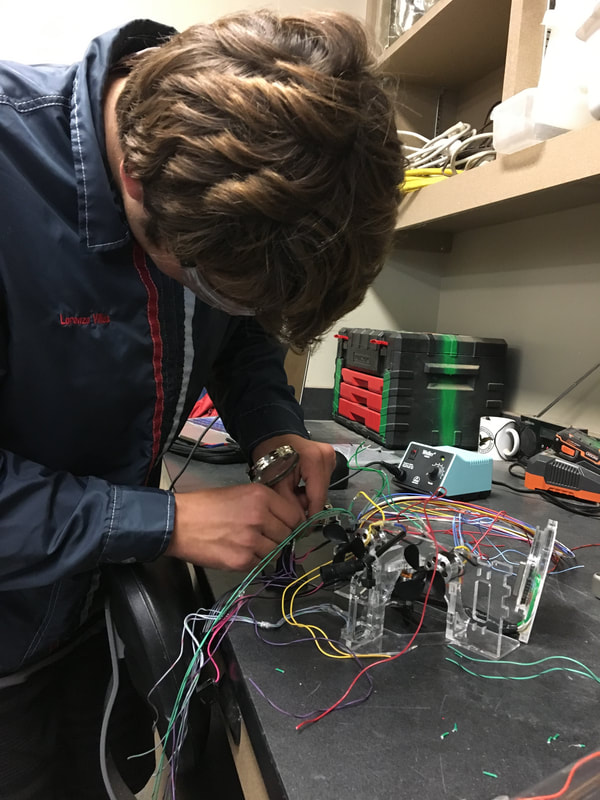

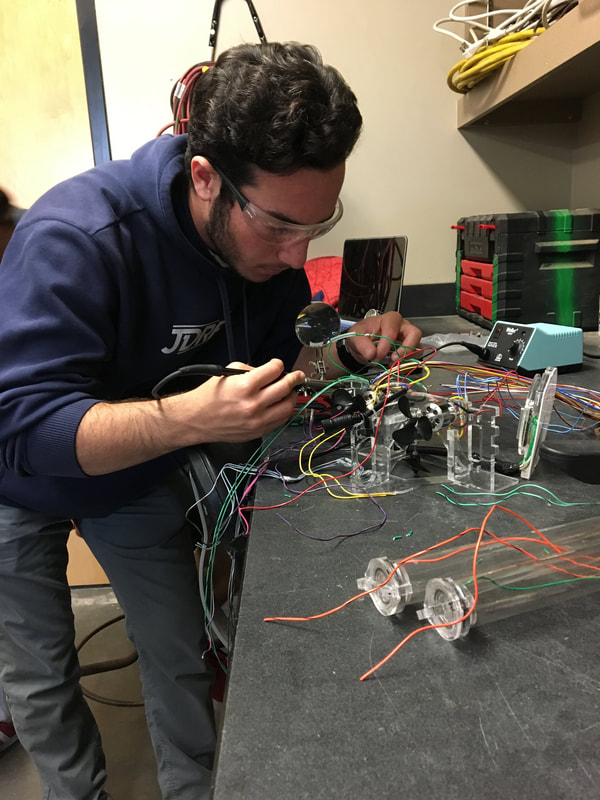

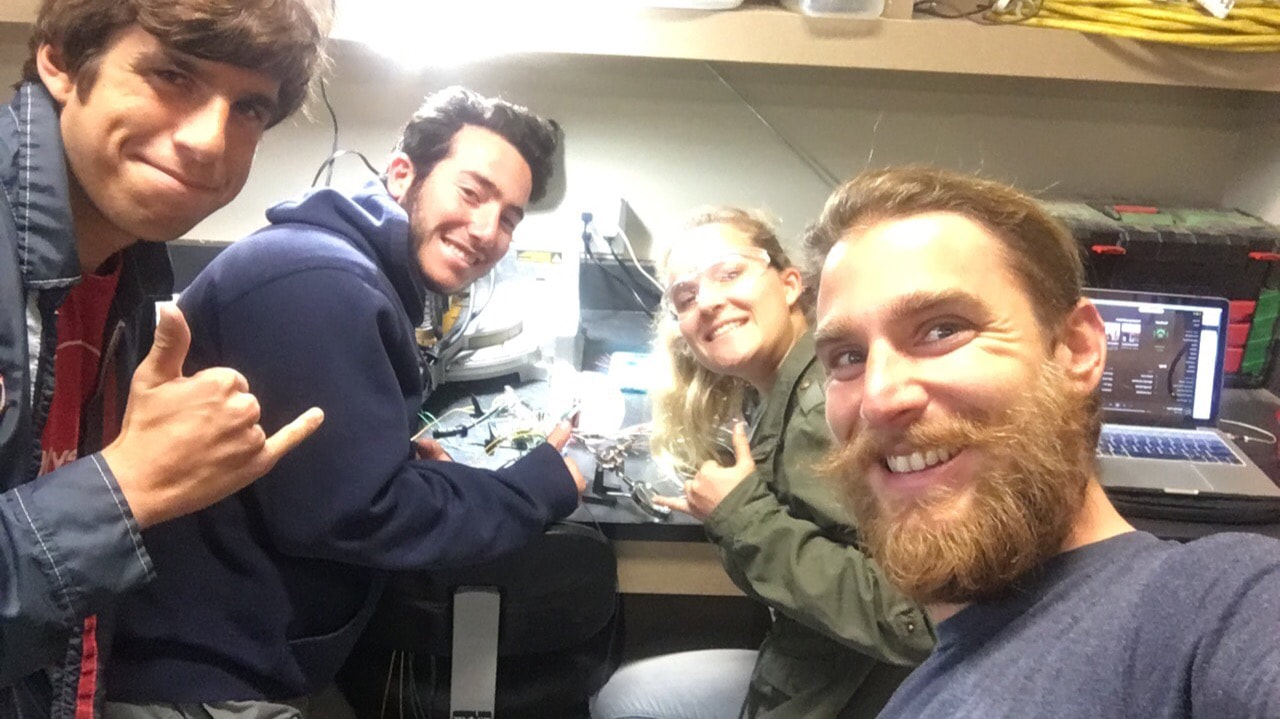

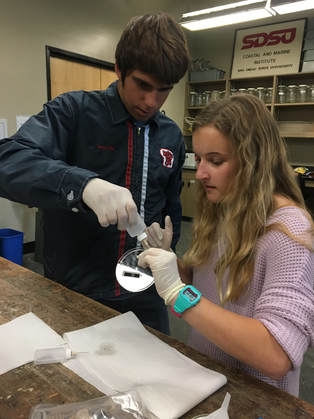

After hours of hard work, Pegasus finally has a whole new harness of wires! After hours of hard work, Pegasus finally has a whole new harness of wires! March 11th 2018 San Diego, CA In following up with our last post, the team and I had our work cut out for us. After giving the epoxy plenty of time to dry, we met on Sunday with the arduous task of rewiring… all of Pegasus. As we explained last time, the DB25 is the vital connection point for the ROV; any and all signals between the ROV and us on the surface go through here. We had our work cut out for us: as the name implies, we had to solder 25 different joints. But that’s only the half of it; we also had to deal with joining old joints, and managing the seemingly endless rainbow array of wires. Here’s what Maddy has to say about our Sunday challenge: “While Sundays are generally considered lazy days, this past Sunday our team was fired up to rewire Pegasus and watch our ROV come to life again. As Jordan mentioned in the last post, we had to call it quits on our last meeting to allow the epoxy to dry, but this meeting we spent hours soldering and rebuilding connections between the DB25 and all of Pegasus’ components. With the goal of getting Pegasus back in the water, we stayed persistent on the tedious task of soldering, which requires much more time and decision making than you would expect. We had to carefully decide where to cut the existing wires in order to make new connections. There’s a few ongoing lessons here: measure twice and cut once, work smarter and not harder, and take the time needed to finish a job correctly. We stayed true to these important lessons as we meticulously rebuilt the connections for the port, starboard, and vertical motors, port and starboard battery tubes, IMU sensors, light cubes, and tether. Unfortunately, we didn’t have a heat gun to secure the heat shrink over the soldering sites, so we weren’t able to power Pegasus up. It was still a very productive day, however, and hopefully these newly rewired connections to the DB25 will solve the issue the ROV has been having!” From left to right: Lorenzo, Jordan, and Maddy all take turns soldering new connections As it turns out, failure is the best teacher. As of right now, after all of our hard work, Pegasus is still not operational. We’re confident that we followed the directions, and worked to the best of abilities. However, some issues are unforeseeable. We’re still troubleshooting, and thanks to the engineers at OpenROV I’m confident that we’ll have Pegasus up and running in no time! Special thanks to Zack and Lorah for taking time to help me troubleshoot over the phone.

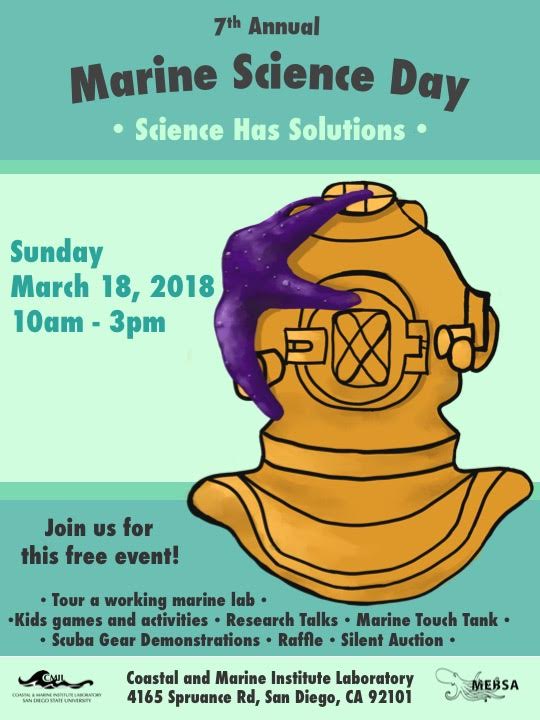

Don’t forget to check out Marine Science Day on Sunday March 18th at the Coastal and Marine Institute! Project Pegasus will be there alongside the Edwards Lab and the rest of the labs at CMIL to showcase our awesome projects! That’s all for now, stay tuned for more. Cheers, -Baron von Urchin

0 Comments

Maddy, Lorenzo, and Jordan rebuild the new DB25 endcap Maddy, Lorenzo, and Jordan rebuild the new DB25 endcap 3/6/2018 San Diego, CA Project Pegasus has been a roller coaster of a ride since its inception last Spring (2017). After a long hiatus, we’re finally able to make the necessary repairs to get Pegasus back in the water. After a lot of head scratching and troubleshooting, we finally realized that the DB25 connector was fried. There about 25 different wires that provide power and information to Pegasus; think of the DB25 as the place where your skull meets your spine. One end of the DB25 is fixed in an “endcap” which seals off the e-chassis from the outside environment. The wires pass through the endcap and are dispersed across the body of Pegasus. The other end of the DB25 connector is mounted to the e-chassis, which is essentially Pegasus’s brain. All systems looked good after we rebuilt the starboard battery tube and controller board, but still Pegasus wasn’t turning on. Power simply wasn’t getting from the battery tubes to the e-chassis. It’s going to take us a little while to rewire Pegasus, which is easier said than done. Here’s Jordan had to say about our pre-rewiring prep: “The ROV and our team have been through a lot over the past year or so. It was sad to see that our DB25 pin, which controls where all the power from the batteries go, was fried. This means that we will need to essentially rewire the majority of the ROV. It is OK though because soldering is one of the most interesting parts of the build! Wire management is also a big concern for our team. We debated over the best places to cut the wires in order to ensure the best wire management as well as least amount of soldered connections.

Today we had to look up some old instructions and rebuild the end cap with a new DB25 connector that we got from OpenROV®. We had to revert back to solvent welding with the dropper that is slightly to wide to allow the liquid to drip slowly. We were able to solvent weld the pieces of plastic together and epoxy the DB25 connector in the end cap, in order to waterproof this portion. After about 2 1/2 hours of work we realized that we had to wait at least another hour for the epoxy to dry before we could even start soldering the new joints, so we decided to save that for another day. We did, however, solder little pieces of solder onto the ends of the batteries so that they would stay in contact with each other in the battery tubes.” Stay tuned! The team and I are meeting next week to rewire Pegasus and get it ready for its public debut at CMIL’s Marine Science Day! Cheers, -Baron von Urchin |

AuthorPike Spector is currently a Research Operations Specialist with Channel Islands National Marine Sanctuary Archives

August 2022

Categories |

RSS Feed

RSS Feed